SpeedSet Orca 1060

High-speed sheet-fed water-based inkjet printer for the packaging market

Are you a packaging converter seeking a cost-effective way to print short runs of packaging?

Then get ready to print at killer speeds and dive into a whole new world of options!

Built to grow with your business

- Sheetfed water-based inkjet printer

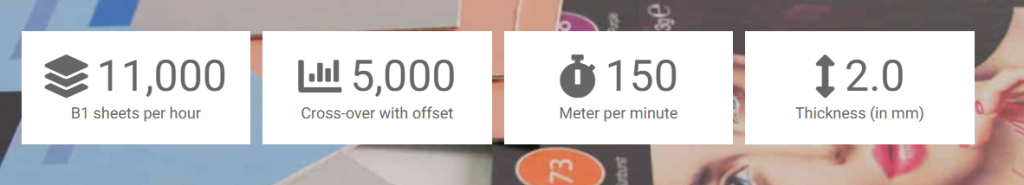

- Up to 11,000 B1 sheets/hour

- Up to 1060 mm x 750 mm (41.7 inch x 29.5 inch)

- CMYK (up to 7 colors optional) + primer + varnish

Nine reasons to choose the SpeedSet Orca

Productivity

The SpeedSet Orca 1060 boasts an impressive speed of up to 11,000 B1 sheets per hour, making it the fastest digital press for packaging available.

Unbeatable speed to market

With digital printing’s ‘right first time’ advantage, startup is swift, and job switching is effortless. This quick turnaround supports on-demand printing and is great for getting diverse packaging designs to the shelf in no time.

Offset-like print quality

Sheet FeWith a resolution of 1200 dpi, the SpeedSet Orca delivers sharp text. It also delivers an extensive color gamut that meets industry standards.

Cost-effectiveness

SpeedSet Orca printing offers significant cost advantages over offset printing. It boasts shorter setup times, reduced material waste, and efficient variable data printing, while it needs no color separation and incurs lower maintenance expenses. The SpeedSet Orca can print all runs up to about 5000 cheaper, allowing you to focus your offset litho operations on longer print runs, thus making it more efficient.

Extensive media range

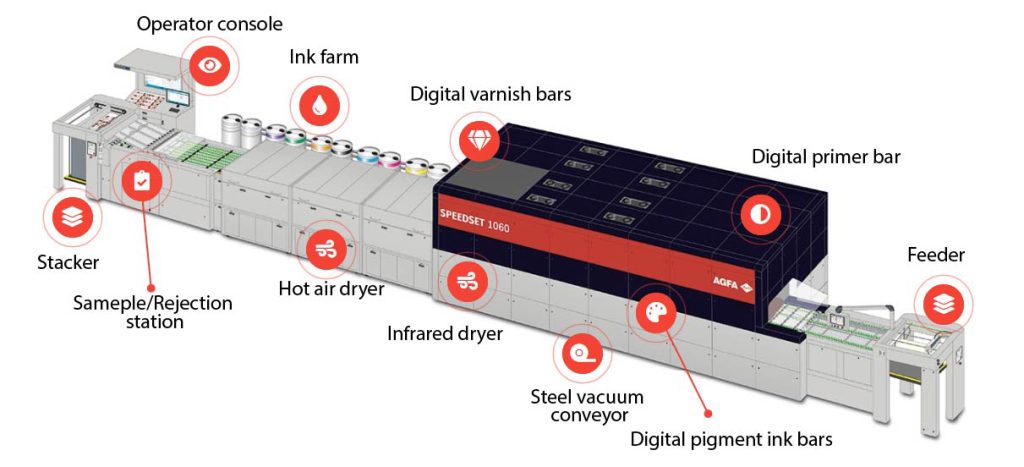

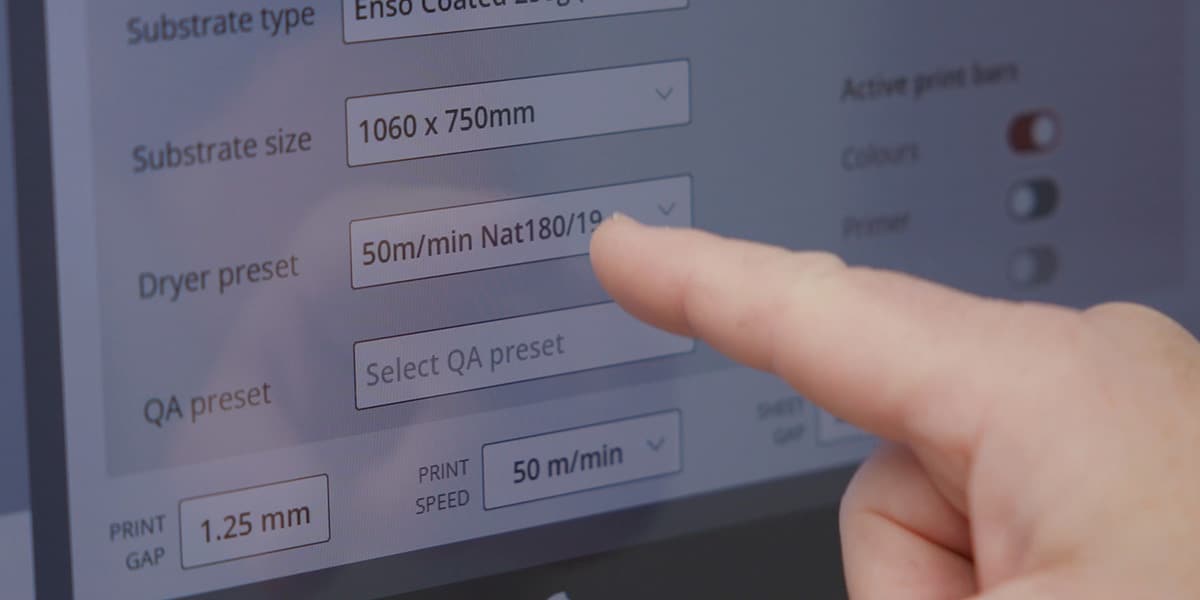

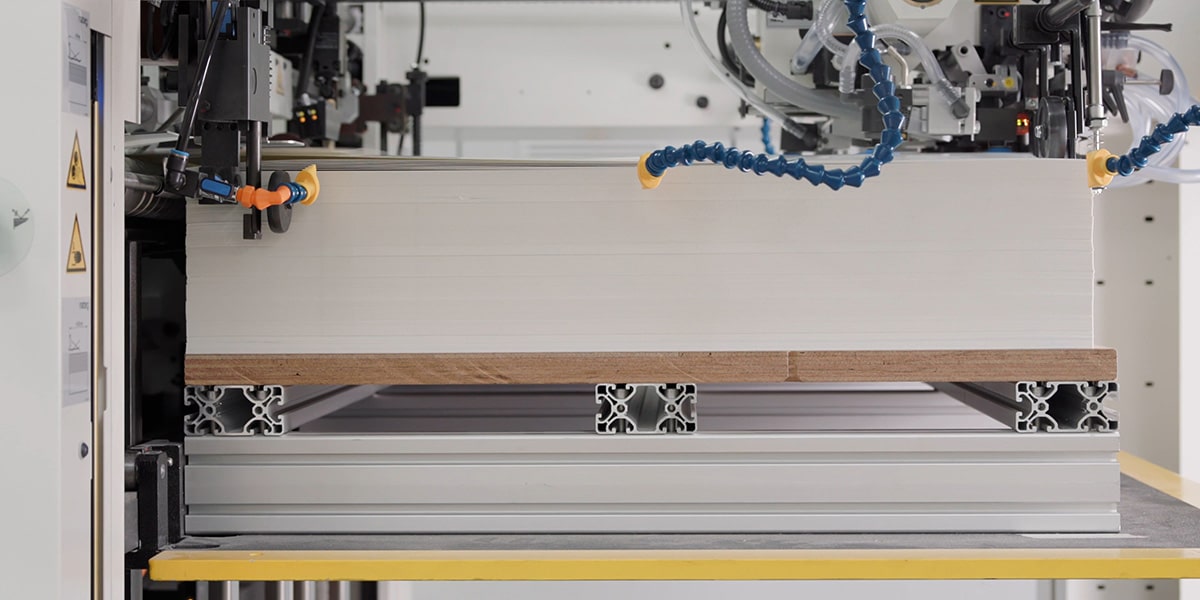

This press accommodates a wide range of substrates, from folding carton and micro-flute to various paper types, making it suitable for applications like retail- or shelf-ready food and beverage packaging. The substrate thickness ranges from a 0.2 mm paper to a 2 mm microflute, offering versatility for various applications and requirements. The patented conveyor vacuum system effortlessly handles diverse materials, pushing productivity to new heights.

Low ink consumption

The digital application of the water-based primer with a very low wet thickness enhances image quality, expands the color gamut, and decreases ink consumption. This not only leads to cost savings, but also reduces environmental impact. Digital printing of both primer and varnish allows for selective application only where needed

Differentiation

A fully digital solution enables you to customize or personalize each individual print, facilitating product differentiation.

Sustainability

The SpeedSet Orca uses Agfa’s water-based pigment inks, primer and varnish that are safe for press operators, and comply with food-safety regulations. Adding to the sustainability credits is the fact that a digital press lets you start print jobs without wasting consumables or media.

Powered by Agfa’s Asanti workflow software

Agfa’s Asanti workflow software enhances operational efficiency, and seamlessly interfaces with ERP and MIS systems, streamlining your entire print production workflow.

Get a complete overview

Features

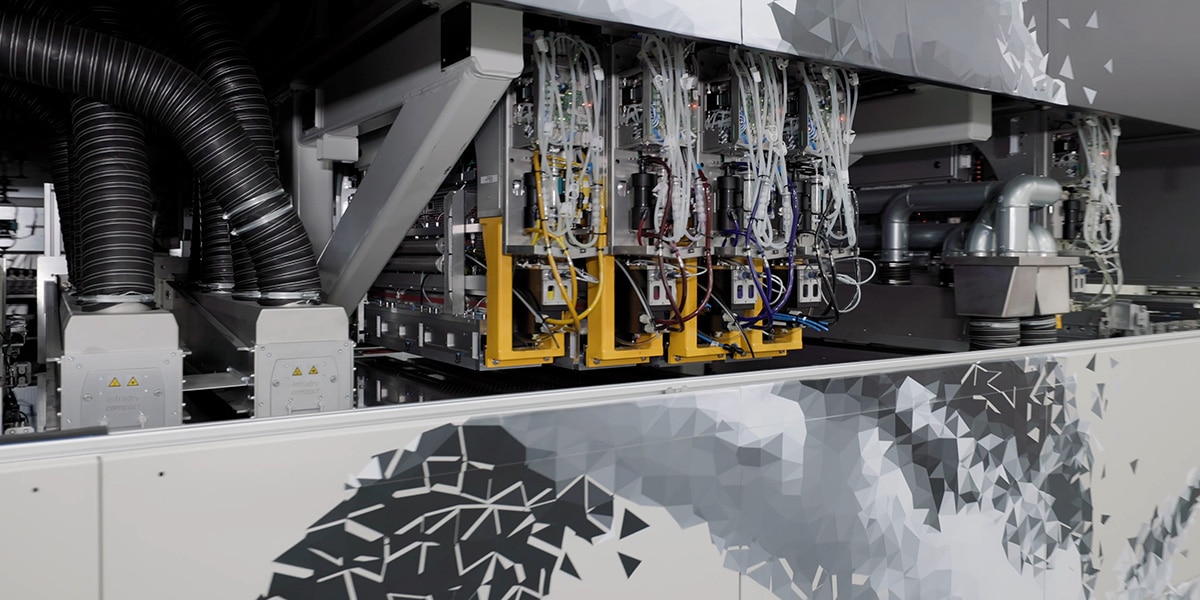

A closer look

SpeedSet 1060

Alignment

Primer bars

IR dryer

Confidence strip

Print sample beer packs

Sample reject area

Quality check

Quality check

Console

SpeedSet 1060

Feeder

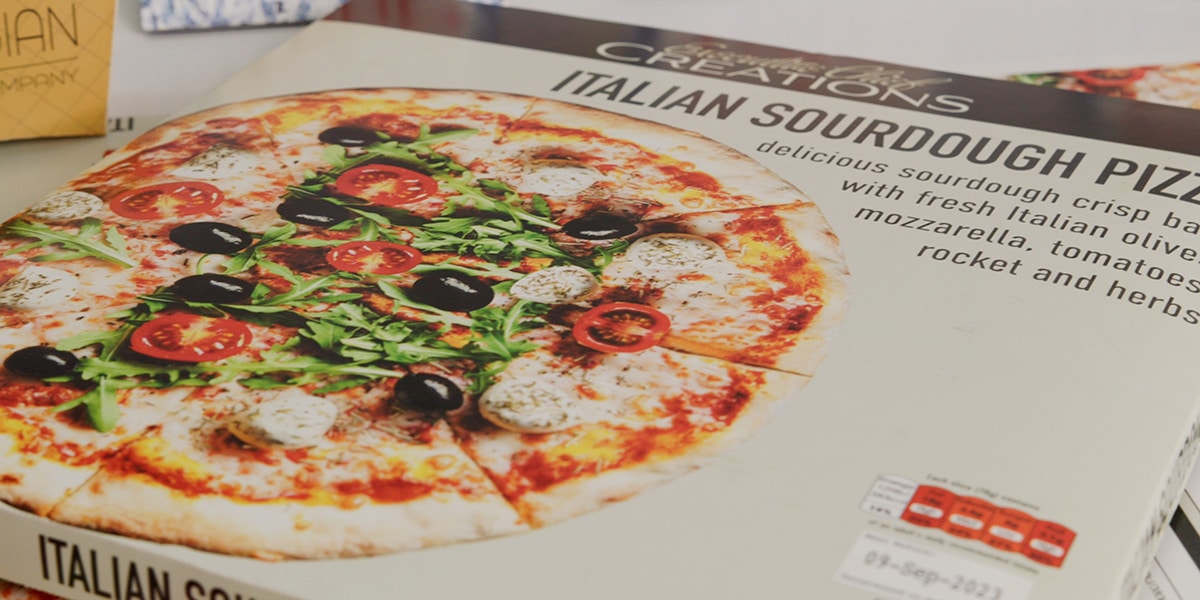

Pizza box print sample

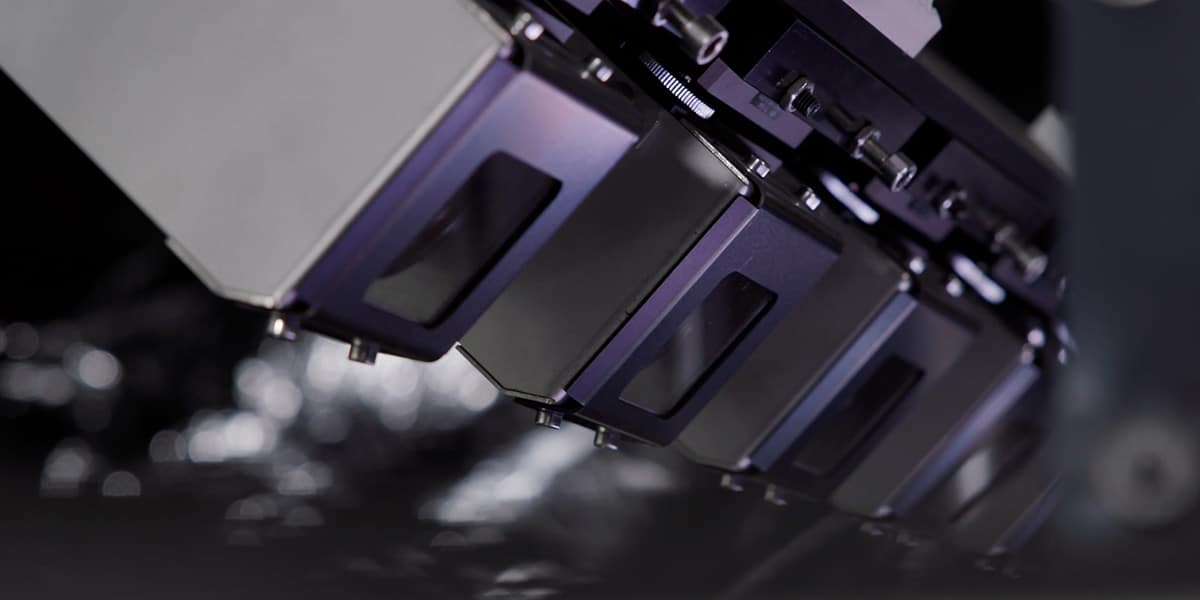

Print bars

Confidence strip

Varnish bars

Sample reject area

Print sample fries boxes

Working area

Stacker