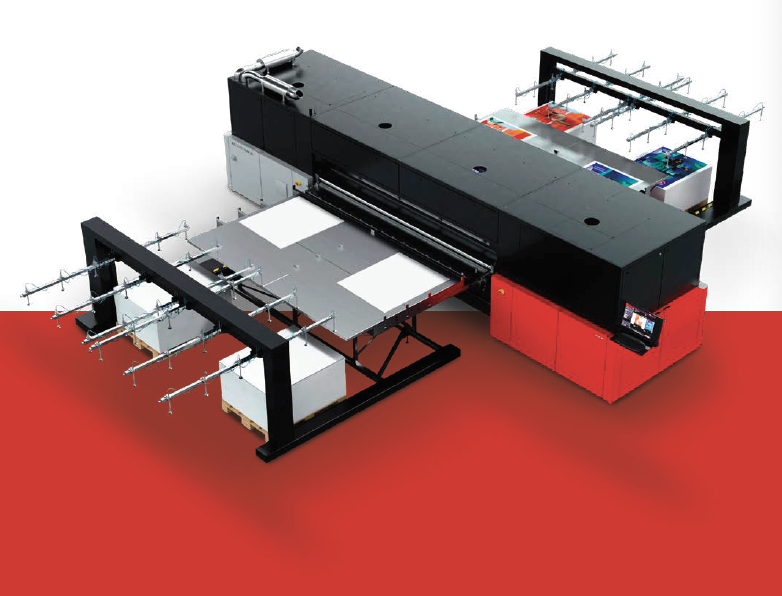

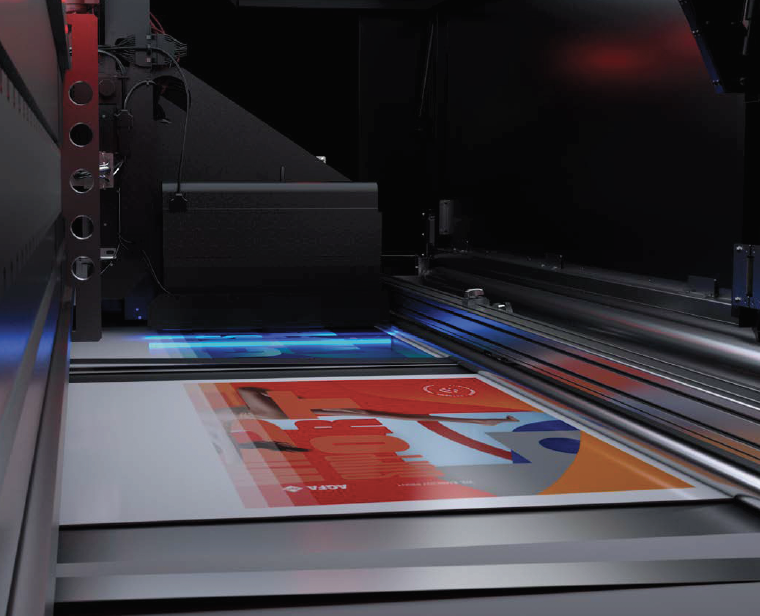

JETi Tauro H3300 LED

Agfa’s flagship hybrid 3.3 m UV inkjet printer for sign and display

Excel in combining award-winning image quality, low ink consumption and productivity. With the Jeti Tauro H3300 LED, you will produce lively UV-cured prints up to 3.3 m wide at up to 453 m2/h. Whether you require this hybrid printer to print boards in full automation, semi automation, or manual loading and unloading, or whether you need to print flexible media on roll, the Jeti Tauro H3300 LED can do it all.

100% LED UV-curing

Relying 100% on fast UV LED curing, the Jeti Tauro H3300 LED comes with a number of economic, ecological and business-generating benefits:

- LEDs are cool to the touch and have minimal heat output, which is why they allow for a broader scope of print applications. They enable you to print on heat-sensitive substrates such as thin sheets, self-adhesive sheets or stretched PVC materials, for example. Limited heat generation also enables very stable calibration.

- LED lamps can be switched on and off instantly, without any degradation of intensity. That means there is no lamp warm-up time or delay for shutter motion. The result? Faster operations and higher productivity.

- LEDs last for at least 10,000 hours each. They generate a consistent UV output throughout that period, which guarantees a consistent curing of the ink, hence consistent image quality.

- LEDs have a low energy consumption, which leads to significant power savings and a higher ROI in the long run.

- As UV LED lamps don’t contain mercury, there is no need for mercury disposal or any related costs. Also, LEDs don’t produce ozone gas that needs to be extracted by ventilation.

Industry-recognized quality and productivity

Choosing between impressive print quality or productivity is a thing of the past. With the Jeti Tauro H3300 LED, you’re guaranteed both award-winning image quality and a print speed of up to 453 m2/h. Expect only smooth, vibrant, detailed prints through rapid UV LED-curing of Agfa’s signature high-pigmented UV inks – this hybrid UV inkjet workhorse delights every time.

Heavy-duty robustness

In the Jeti Tauro H3300 LED, you’ll find a heavy-duty hybrid printer, ruggedly built to easily handle extreme workloads, multiple shift operation and 24/7 printing. Suited for a variety of rigid and flexible substrates (e.g. paper, styrene, corrugated cardboard and corrugated polypropylene) up to 3.3 m wide, this hybrid revelation offers you countless options to create eye-catching large-format prints.

Transform your productivity

The Jeti Tauro H3300 LED features 60 fast-firing Ricoh inkjet print heads – 48 of which print in color, and 12 of which are dedicated to white and/or primer printing. Add to that Agfa’s signature UV LED-curable inks and Agfa’s print process know how and you have the perfect combination of productivity and quality. This flagship printer even throws in several automation options.

Extremely vivid prints

Whatever you are creating, the Jeti Tauro H3300 LED produces detailed, vibrant results every time. While its 7-picoliter print heads guarantee an outstanding resolution of 635 x 1200 dpi in all print modes, the UCR/GCR ink-saving algorithms embedded in Asanti ensure the lowest ink consumption. Through 6-color printing, including light black (CMYKLcLk), the engine guaranties a perfect neutral gray balance over the total tonal range.

Dedicated Sign & Display workflow software

Simplify & automate

The Jeti Tauro H3300 LED is driven by Agfa’s wide-format workflow software Asanti, which controls the entire printing process from prepress to production and finishing. As such, it simplifies, optimizes and automates as many steps as possible, offering you a high-performance solution for increased productivity.

Moreover, Asanti’s smart imaging algorithms help optimize your inkconsumption, and consequently, reduce your costs an environmental footprint. Asanti’s comprehensive integration of file handling, color management and preflighting guarantees smooth, error-free jobs ready to send to the appropriate wide-format output devices.

Among other possibilities that Asanti offers are the creation of personalized productivity modes and job parameter reporting for increased control. The software is completed by Asanti StoreFront, a web-to-print solution that lets you create and manage online stores and automatically process print orders.

The perfect match: Agfa-made inks

Agfa’s UV-curable LED inks: always spot on

Specially formulated to print on both rigid and flexible media, Agfa’s UV LED inks broaden the scope of possible applications. Whatever the medium or intended use (indoor versus outdoor), accuracy and excellent adhesion are a given.

Vibrant colors, impressive results

Agfa-made UV inks boast a wide color gamut and high color vibrancy, resulting in lively yet natural prints that will impress and inspire your clients and prospects every time. Agfa inks are LED cured instantly, delivering consistent high-quality results, batch after batch. What’s more, this vividness is created to last, even when subjected to outdoor weather conditions.

The lowest ink consumption out there

Thanks to Agfa’s patented ‘Thin Ink Layer’ technology, which involves the optimal dispersion and high pigment load of Agfa-made inks combined with Asanti’s algorithms, ink consumption per square meter is the lowest on the market. However, using this pigment dispersion technology to save ink does not mean that the Jeti Tauro H3300 LED compromises on quality or performance in any way. Quite the opposite is true – it results in eye-catching prints while also preventing clogging, offering stable jetting performance and helping you save on your budget.

Advanced white printing and ink management

The Jeti Tauro H3300 LED supports high-productivity white printing in multiple modes on both rigid and roll media. Thanks to its stirring functionality, the engine keeps the white ink in motion. Ink lines in the main ink supply chain are under constant circulation – all the way to the temperature-controlled printer heads – limiting the risk of clogging.

Primer option for better surface tension

Difficult substrates can pose adhesion and durability challenges for inkjet printing. That’s where the Jeti Tauro H3300 LED’s primer option comes in. A rapidly deposited (concurrent) primer ensures outstanding adhesion on the most difficult non-absorbent

media types such as acrylic – applied either as a ‘fill’ (the whole area) or ‘mask’ (printed areas only). The UV-cured primer formulation is optimized for Ricoh heads and applied in low-coverage percentages, so that it hardly influences your cost per square meter of output.

Technical specifications – Jeti Tauro H3300 LED

| MODELS | |

| Three configurations, depending on the applications that you run | Jeti Tauro H3300 LED 6C – 6 colors (48 heads) Jeti Tauro H3300 LED 6C W12 – 6 colors and white (60 heads) Jeti Tauro H3300 LED 6C W8P4 – 6 colors, white and primer (60 heads) |

| MEDIA & PRINTING SPECIFICATIONS – SHEETS & BOARDS | |

| Maximum width | Base engine: 3.34 m (131.49” = 10.95 ft) Loader: 3.30 m (130” = 10.8 ft) Unloader: 3.30 m (130” = 10.8 ft) |

| Maximum length | Base engine: 4.0 m (157.48” = 13.12 ft) Loader: 2.1 m for flexible sheets (82.68” = 6.89 ft)/ 2.44 m (96.06” = 8.01 ft) for boards Unloader (sheets & boards): 2.44 m (96.06” = 8.01 ft) |

| Minimum size | Base engine: A2: 42.0 cm x 59.4 cm (16.5” x 23.4”) Loader: A1: 59.4 cm x 84.1 cm (23.4” x 33.1”) (in portrait) Unloader: A1: 59.4 cm x 84.1 cm (23.4” x 33.1”) (in portrait) |

| Thickness | Base engine: min. 0.2 mm (8 mil) – max. 5 cm (1.97”) media-dependent Loader: min. 0.2 mm (8 mil) – max. 2 cm (0.8”) media-dependent Unloader: min. 0.2 mm (8 mil) – max. 2 cm (0.8”) media-dependent |

| Weight | Base engine: 10 kg/m² (2 lb/ft2) evenly distributed – Sheets: from 200 g/m² (0.04 lb/ft2) Loader: 10 kg/m² (2 lb/ft2) with max 25 kg (55.1 lb) per sheet/board – Sheets: from 200 g/m² (0.04 lb/ft2) Unloader: 10 kg/m² (2 lb/ft2) with max 25 kg (55.1 lb) per sheet/board – Sheets: from 200 g/m² (0.04 lb/ft2) |

| Borderless printing | Yes, with protection paper or tape on the belt |

| MEDIA & PRINTING SPECIFICATIONS – MASTER ROLL-TO-ROLL | |

| Maximum width | Single roll: 3.3 m (130” = 10.83 ft) – Dual roll: 1.6 m (63” = 5.25 ft) |

| Minimum width | Single roll: 61 cm (24” = 2 ft) – Dual roll: 61 cm (24” = 2 ft) |

| Maximum length | Full roll length (depends on total roll thickness, diameter and weight) |

| Thickness | Max: 2 mm (0.08”) (80 mil) – Min: 0.2 mm (0.008”) (8 mil) for single and dual roll |

| Maximum weight | Master roll single: up to 700 kg (1543.24 lb) in full width, mounted at the center of the shaft Master roll dual: up to 700 kg (1543.24 lb) per roll in full width, mounted at the center of the shaft *the max weight depends on the roll width |

| Maximum roll outside diameter | 60 cm (23.6”) for single and dual roll |

| Roll mounting | For single and dual roll: pneumatic shafts for cores of 76.2 mm – 3” (standard) and 152.4 mm – 6” (optional) |

| Borderless printing flexible media | Yes, with tape on the belt. |

| PRODUCTIVITY | |

| Up to 453 m²/h (4876 ft²/h) (for automation dependent on size and number of boards) | |

| MEDIA | |

| Media types | Rigid as well as flexible media. Check with your local Agfa representative for a detailed list. |

| PRINT HEADS & INKS | |

| Print heads | Piezoelectric Ricoh MH5420 |

| Ink | CMYKLcLk + white and primer |

| IMAGE & TEXT QUALITY | |

| Image quality | Resolution up to 635 x 1200 dpi |

| Text quality | 4 point |

| ENGINE DIMENSIONS & WEIGHT | |

| Printer dimensions (H x W x L) | Crated: 2.45 m x 2.26 m x 8.45 m (96.45” x 89” x 332.7”) (8 ft x 7.4 ft x 27.7 ft) Uncrated: 2.3 m x 2.1 m x 8.2 m (90.5” x 82.7” x 322.8”) (7.5 ft x 6.9 ft x 26.9 ft) |

| Printer weight (Unit comes in one crate) | Crated: 10,000 kg (22,046 lb) – Uncrated: 7,500 kg (16,535 lb) |

| Loader/Unloader dimensions (H x W x L) (Each unit comes in a separate crate) | Loader & unloader, crated: 2.06 m x 2.3 m x 4.62 m (81.1” x 90.5” x 182”) (6.8 ft x 7.5 ft x 15.2 ft) Loader, uncrated: 1.65 m x 4.22 m x 4.24 m (65” x 166.2” x 166.9”) (5.4 ft x 13.8 ft x 13.9 ft) Unloader, uncrated: 1.65 m x 4.22 m x 4.04 m (65” x 166.2” x 159”) (5.4 ft x 13.8 ft x 13.3 ft) |

| Loader/Unloader weight (Each unit comes in a separate crate) | Crated: 2100 kg (4630 lb) – Uncrated: 1800 kg (3968 lb) |

| Master roll-to-roll dimensions (H x W x L) per unit (Comes in two crates (one crate/unit)) | Crated: 1.48 m x 1.47 m x 4.28 m (58.3” x 58” x 168.5”) (4.8 ft x 4.8 ft x 14 ft) Uncrated: 1.2 m x 1.3 m x 4.1 m (47.2” x 51.2” x 161.4”) (3.9 ft x 4.3 ft x 13.45 ft) |

| Weight master roll-to-roll | Weight per crate: 1090 kg (2403 lb) – Weight per unit: 700 kg (1543.2 lb) |

| ROOM CONDITIONS | |

| Temperature | Between 16-25°C (61-77°F) |

| Relative humidity | Between 40-60% |

| ELECTRICITY & COMPRESSED AIR | |

| Electricity – base engine | 400-480 VAC, 3-phase + Ground, 50/60 Hz – Max current: 52 A (for 400 V) / 43 A (for 480 V) |

| Electricity – loader | Single Phase + Ground, 230V 50/60Hz – Max current: 8 A |

| Electricity – unloader | Single Phase + Ground, 230V 50/60Hz – Max current: 5 A |

| Electricity – Master roll-to-roll | 400-480 VAC, 3-phase + Ground (no neutral), 50/60 Hz – Max current: 1.5 A (for 400 V) / 1.2A (for 480 V) |

| Compressed air – base engine | Min. 6 bar (87 PSI) – Air consumption: 5.86 cf (166 l/m) (43.85 US gal/min) |

| Compressed air – master RTR | Min. 6 bar (87 PSI). No dedicated connection. Roll-to-roll units (rear and front) are connected directly to the base engine. |

| Compressed air – loader | Min. 6 bar (87 PSI) – Air consumption 17.66 cfm (500 l/m or 132.08 US gal/min) |

| Compressed air – unloader | Min. 6 bar (87 PSI) – Air consumption 10.59 cfm (300 l/m or 79.25 US gal/min) |

| SYSTEM INTEGRATION RIP/WORKFLOW SOFTWARE | Asanti, StoreFront, PrintSphere, third-party RIPs |