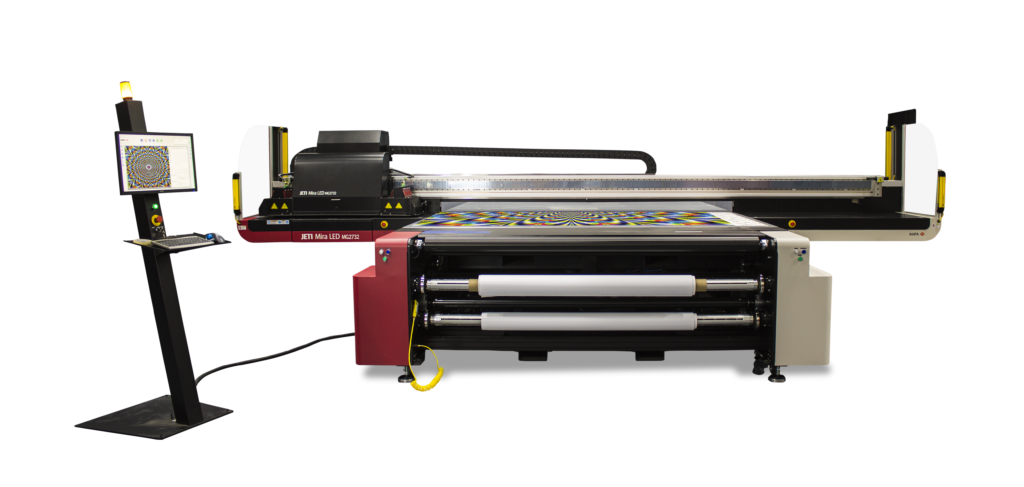

JETi Mira LED

Jeti Mira LED – A versatile printing solution

This award-winning flatbed printer now relies on UV LED curing to offer you impressive print quality on a wide variety of media. Accelerate the printing process to 248 m²/h, use the dockable roll-to-roll extension or opt for 3D Lens Technology printing whenever you need to.

The powerful and award-winning Jeti Mira is a moving-gantry flatbed printer specially designed to offer you optimal flexibility. Prints of up to 2.69 m wide, two table versions, LED curing and 3D Lens Technology – the latest Jeti Mira has it all.

Driven by Asanti workflow technology, integrable with cloud service for data exchange PrintSphere and optimized to work with Agfa’s highpigmented UV-inks, the Jeti Mira takes on any challenge. Generating high-quality, six color (CMYKLcLm) + white prints, with optional varnish and primer, it perfectly meets the dynamic demands of mid- to high-end sign and display printers.

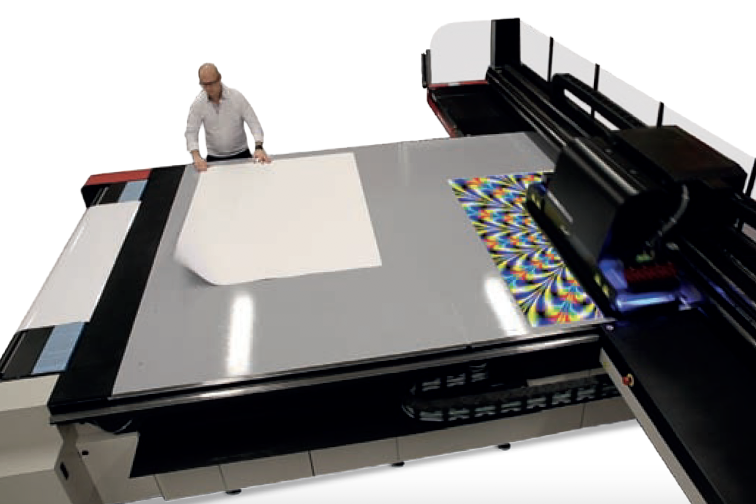

A true flatbed

The Jeti Mira is a highly reliable and ruggedly built flatbed printer with a roll-to-roll option. Available with a table depth of either 1.6 m or 3.2 m and a table width of 2.69 m, it is suited for even the broadest of jobs. Thanks to its precise moving-gantry architecture, the engine offers you optimal flexibility and high-quality printing, both for rigid and flexible substrates.

Linear motor

With two rows of fast-firing Ricoh MH5420 inkjet print heads, the speedy flatbed printer offers you outstanding productivity. In addition, the Jeti Mira is equipped with a linear motion system which achieves a very precise drop positioning and results in further improvements in image quality. With its UV LED curing, the Jeti Mira brings additional benefits in power consumption and application scope.

Roll-to-roll option

A versatile, powerful printing solution, the Jeti Mira features an optional roll-to-roll system that can be attached to the front of the flatbed table. It thus reduces the travel distance for print media, decreases the chance of skewing and improves accuracy on the Y axis.

Detach the module to keep it out of your way while performing rigid jobs or just leave it docked, whichever is more convenient for you. The roll-to-roll system fits in perfectly with the moving gantry and allows minimal waste production while printing on flexible media.

‘Print & Prepare’ mode

Thanks to its ‘Print & Prepare’ mode, the Jeti Mira allows you to load one side of the table while the other side is printing. As such, this feature reduces downtime and increases your productivity. It’s perfect for large boards, smaller boards and double-sided images.

Furthermore, operators working in ‘Print & Prepare’ mode can rely on a mirrored vacuum system and perfectly symmetrical table, with vacuum sections on both sides of the engine. Confusion over media layout? Not with the Jeti Mira.

Up and running

Its robustness allows the Jeti Mira to meet the demands of a heavy workload. Its ink system – both print heads and ink reservoirs – are temperature controlled, ensuring that your ink hits media at the ideal temperature and no blockages are formed. Thanks to the shuttle’s accessibility, maintenance of the print heads has never been easier.

Focus on automation

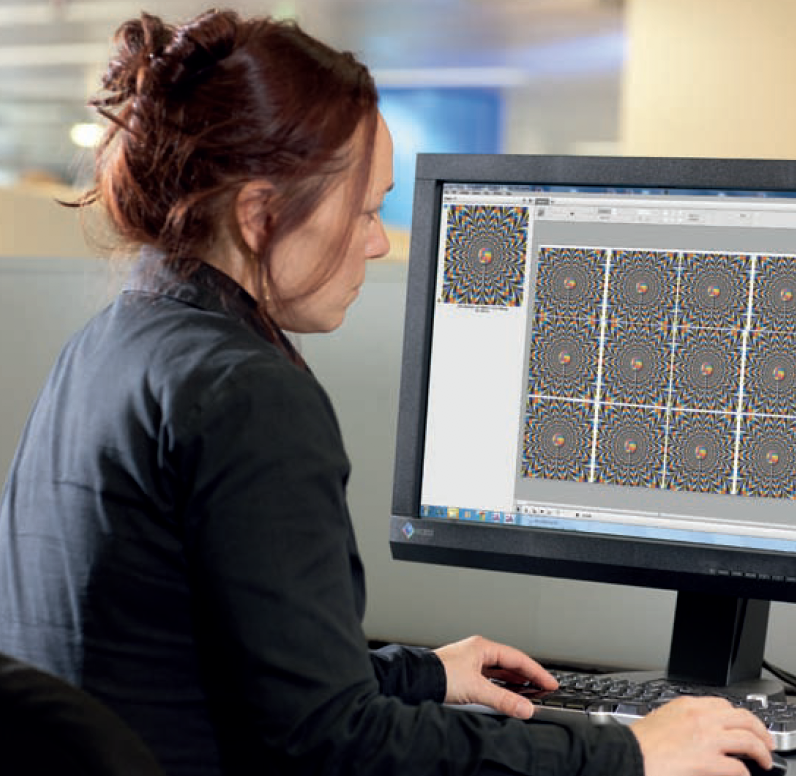

Powered by Asanti

The Jeti Mira is driven by Agfa Graphics’ wide-format workflow software Asanti, which controls the entire printing process from prepress to production and finishing. As such, it simplifies, optimizes and automates as many steps as possible, offering you a highperformance solution for increased productivity. Moreover, the smart Asanti algorithms reduce your ink consumption, and consequently, your costs and environmental footprint.

Asanti’s comprehensive integration of file handling, color management and preflighting guarantees error-free jobs ready to send to the appropriate wide-format output devices. It is completed by Asanti StoreFront, a web-to-print solution that lets you create and manage online stores and automatically process print orders.

Integrable with PrintSphere

As a highly-advanced printer powered by Asanti, the Jeti Mira integrates perfectly with PrintSphere, Agfa Graphics’ cloud-based service for production automation, easy file sharing and safe data storage. This integrable cloud service offers a standardized way for print service providers to automate their workflows and facilitate data exchange with customers, colleagues, freelancers, other departments and other Agfa solutions.

Vivid colors, high performance

Wide color gamut, no matter the medium

Agfa-made UV inks boast a wide color gamut and high color vibrancy in both indoor and outdoor applications. Providing outstanding adhesion – even on the most difficult substrates – these inks are your best option in terms of flexibility, image longevity and outdoor resistance. All of our UV inks — white and color — offer outstanding, stable jetting performance and deliver the same high-quality results, batch after batch.

Agfa’s UV-curable LED inks: always spot on

Relying on LED technology, our specially-formulated UV LED inks can print on heat-sensitive substrates, thus broadening the scope of possible applications. They are both customized and versatile, developed with a view of the many different media they are intended for, as well as the specifications of different print engines. Our inks for flexible media, for example, are perfectly suited for stretchable and

bendable materials.

Vivid prints, low ink consumption

Thanks to the high pigment load of our inks and the benefits of Asanti’s algorithms, ink consumption per square meter is the lowest on the market. The amount of ink needed being one of the most important factors in calculating the cost of ownership for inkjet engines, this is a true asset that has been acknowledged by multiple awards.

Moreover, this ‘thin ink layer’ pigment dispersion technology does not mean the Jeti Mira compromises on quality. Quite the opposite is true – and not only does it result in eye-catching prints; it also helps preserve the environment and saves on your budget. In short, these inks offer the best possible price/quality ratio.

Advanced white printing and white ink management

Printing on backlit media? Creating an opaque white background? Using white as a spot color? The Jeti Mira supports white printing in multiple modes (e.g. pre-white, post-white, sandwich white) on both rigid and roll media. Thanks to its stirring functionality, the Jeti Mira keeps the white ink in motion at all times. Constant recirculation flows along the ink lines – all the way to the temperature-controlled printer heads – limiting the risk of ink resettling and lines becoming blocked or clogged.

Primer option for better surface tension

Difficult substrates – such as polypropylene, PMMA/acrylic, polystyrene, etc. – can pose adhesion and durability challenges for inkjet printing. Opting for the Jeti Mira’s primer option, however, allows you to easily improve surface tension. A quickly-deposited primer ensures better print results – either as a ‘fill’ (the whole area) or ‘mask’ (printed areas only). The UV-cured primer formulation is optimized for the Ricoh MH5420 heads that are incorporated into the Jeti Mira. And because the primer is applied in low-coverage percentages, it hardly influences your cost per square meter of output.

Varnish option and 3D Lens Technology

Looking for something extra to differentiate yourself from the competition? Varnish is the perfect solution. Used as ‘spot’ varnish, it can add a dramatic touch to many different applications, including POP displays, packaging, decorative prints and trade show graphics. Agfa Graphics’ UV-curable varnish is compatible with almost all standard UV-printing media and cures to a perfect gloss or semi-gloss sheen.

Want to take it one step further? Create stunning 3D effects with real stopping power. Using a combination of varnish and image manipulation (e.g. printing transparent lenses), the Jeti Mira knows no print limits. This 3D Lens Technology adds depth to your print results by tuning the size of the varnish lenses and the array in which they are printed, as well as by relying on software elements to enhance pictures. 3D printing is a standard feature for Jeti Mira engines with varnish option in the first year. After this one-year license, you will be able to opt

for a lifetime license.

Specifications – Jeti Mira MG2732 HS LED

| MEDIA & PRINTING SPECIFICATIONS | |

| RIGID MEDIA | |

| Maximum width | 2.69 m (8.82 ft) |

| Maximum length | 3.2 m (10.49 ft) |

| Minimum size | DIN A4 (21 cm x 27.7 cm) landscape |

| Thickness | Min. 0.2 mm (0.008”) – max. 50.8 mm (2”) |

| Maximum weight | 37 kg/m2 (7.57 lb/ft2) |

| Borderless printing | Up to 2.69 m x 3.20 m (8.82 ft x 10.49 ft) |

| FLEXIBLE MEDIA | |

| Max-min print width | 2.05 m (6.72 ft) – 330 mm (13”) |

| Max-min print height | Full roll length – n/a |

| Max-min roll width | 2.10 m (6.88 ft) – 330 mm (13”) |

| Maximum length | Depends on total roll weight |

| Max-min media thickness | 3.2 mm (1/8”) – 0.2 mm (1/64”) |

| Maximum weight | 100 kg (220 lb) |

| Maximum roll outside diameter | 305 mm (12”) |

| Roll core | 7.62 cm (3”) (standard) or 15.24 cm (6”) (with adapters) |

| Media skew | Max. 3 mm on 10 m printing |

| Borderless printing flexible media | Up to 2.05 m (6.72 ft) |

| PRODUCTIVITY | |

| Draft mode | 248 m2/h (2669 ft2/h) |

| Express mode | 165 m2/h (1776 ft2/h) |

| Production mode | 83 m2/h (893 ft2/h) |

| Standard mode | 43 m2/h (462 ft2/h) |

| High-quality mode | Positiv: 4-Punkt/Negativ: 6-Punkt |

| High-definition mode | 13 m2/h (139 ft2/h) |

| MEDIA | |

| Media types | Reinforced vinyl, pressure-sensitive vinyl, canvas, fabrics, foam board, corrugated board, lenticular, tile, drywall, glass, sheet, metal, paper, and more |

| PRINT HEADS & INKS | |

| Print heads | Piezoelectric Ricoh MH5420 |

| Ink | CMYKLcLm + white (optional primer or varnish) |

| IMAGE & TEXT QUALITY | |

| High-quality prints | Up to 920 x 1200 dpi |

| Text quality | 4 point |

| ENGINE DIMENSIONS & WEIGHT | |

| Flatbed printer dimensions (H x W x L) | 1.84 m x 6.25 m x 4.4 m (6 ft x 20.5 ft x 14.4 ft) |

| Flatbed printer with roll-to-roll unit dimensions (H x W x L) | 1.84 m x 6.25 m x 4.9 m (6 ft x 20.5 ft x 16 ft) |

| Flatbed printer weight | 3456 kg (7620 lb) |

| Flatbed printer with roll-to-roll unit weight | 4401 kg (9703 lb) |

| ELECTRICITY & COMPRESSED AIR | |

| Electricity | 400Y / 230V, 3-phase 50/60 Hz 25 KVA (35A) |

| Compressed air | 5 cfm continuous air at 100-150 psi (8.3 m3/h at 6.9-10.3 bar) |

| SYSTEM INTEGRATION RIP/WORKFLOW SOFTWARE | Asanti, PrintSphere, third-party rips |