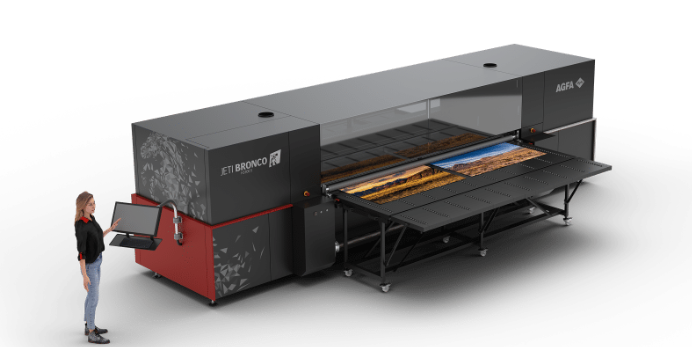

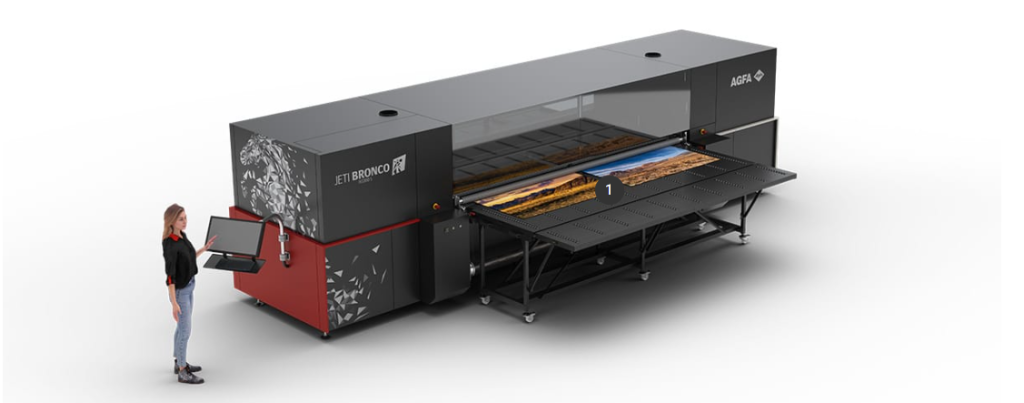

Jeti Bronco H3300

3.3 m wide-format UV LED inkjet printer for rigid and flexible media

Wild horses roam free with grace and agility across vast plains. You’ll find their indomitable spirit in the Bronco inkjet printer too. Saddle up for success with this hybrid inkjet printer offering breathtakingly beautiful print quality.

- Hybrid inkjet printer

- Up to 248 m²/h – 2669 ft²/h

- Up to 330 cm – 130 in

- CMYKcm & white

Why the Bronco is the right beast for you

The Jeti Bronco H3300 wide-format hybrid printer is designed for sign shops and digital printers looking for a combination of versatility, productivity, and excellent print quality. With a 3.3-meter print width, UV LED curing, and a six-color plus white ink set, this print engine is a perfect fit for a wide range of indoor and outdoor print applications.

- Versatile printer that tackles a wide range of rigid and roll media for indoor and outdoor applications

- Productivity enhanced through efficient continuous board feeding & multiple board printing (up to 4 boards simultaneously)

- Single-roll printing up to 3.3 meter wide – independent dual-roll printing up to 1.6 meter wide

- Borderless printing limits post-finishing requirements

- Pre-white, sandwich white and post-white in one run

Built on an industrial framework tailored for enduring steady workloads - Printer technology and graphical user interface based on our Jeti Tauro high-end printing solutions

- Perfect interaction between Asanti workflow software and the printer yields exceptional image quality

- GREENGUARD Gold-certified inks with wide color gamut

- Field-upgradeable from a two- to a four-row engine

Saddle up for success. Roam free and venture into new territories. Upgrade your horsepower.

Discover the Bronco’s great features

The Bronco in action at FESPA Global Print Expo 2024

A wide range of applications

The Jeti Bronco H3300 revolutionizes your business with unparalleled versatility across a spectrum of applications. This hybrid printer excels in producing high-quality prints on uncoated rigid media such as exhibition panels, stage graphics and advertising boards, as well as on roll media like film, vinyl, banners, canvas and coated textiles. UV LED lamps broaden the range of printable media to e.g. thin, heat-sensitive foils, as well as PET or microflute.

The printer’s adaptability also extends to niche products and enables diverse creative expressions and applications in architectural and interior decoration. The white ink function lets you print on transparent materials for backlit applications or use white as a spot color.

Standout features

Single- or dual-roll printing

A single roll can be as wide as 3.3 meters, whereas in dual printing mode, each roll can be up to 1.6 meters wide. Switching between single- and dual-roll printing modes is straightforward, and the rolls can even have different diameters when printing in dual-roll mode.

LED curing

Powerful air-cooled UV LED lights offer substantial energy savings and are well-suited for heat-sensitive materials, thanks to their low energy output. This makes them ideal for printing thin slides, self-adhesive sheets, or stretched PVC materials

Smart Ink Management

Throughout production, the automatic ink management system diligently monitors ink levels. A separate system manages the white ink, overseeing circulation, under-pressure regulation, and cleaning. The white ink tank is also equipped with a stirring mechanism to maintain optimal ink consistency through continuous mixing. The ink refill system is conveniently accessible, allowing for clean and straightforward refilling of the ink containers. RFID tags on the ink bottles ensure accurate and hassle-free refilling of ink containers, even during printing.

Multiple board and borderless printing

The continuous board feeding capacity drastically enhances efficiency and productivity when printing rigid materials. While one board is printing, the next one can already be loaded. This automated process is ideal for volume printing of boards, enabling the simultaneous printing of up to four boards. With the added advantage of borderless printing, post-finishing becomes unnecessary.

Flawless media handling

The printer guarantees precise media loading with automated functionalities embedded in the GUI, such as the media registration bar and head height adjustment. A vacuum system intelligently controlled across four zones maintains consistent vacuum levels throughout the printing process, whether printing on flexible or rigid materials. In addition, the printer is equipped with inflatable airshafts for unwinding and rewinding, complemented by a rewinding tension roller, ensuring excellent material tension and wrinkle-free prints. The carbon-made rear shaft is both lightweight for operator comfort and robust for efficient performance.

Shuttle beam with linear motor

A robust beam with a powerful and precise linear motor provides smooth and silent movement of the print shuttle, ensuring exceptional accuracy in dot placement and delivering outstanding image quality. As set of shuttle safety sensors prevents print heads from touching the substrate and getting damaged.

Ionizer

An ionization bar mounted on the carriage removes electrostatic charges on the substrate, ensuring optimum ink droplet placement.

Protective closure

The safety hood covers the print belt and shuttle, eliminating any potential risks of harm to operators.

Small and large media tables

The Jeti Bronco H3300 comes standard with an additional set of large media tables that can be coupled to the default smaller tables. This makes it possible to print on rigid materials up to a length of 3.2 m.

User-friendly control panel

The printer features an intuitive graphical user interface accessible via a touch screen mounted on a swivel arm, with all settings organized for ease of use. It manages print files efficiently through an internal bitmap server, ensuring fast spooling and secure data transfer. Agfa has standardized this interface across all high-end UV printing systems, making it easy for users to transition between Agfa printers on the shop floor.

Pedal controlled

The start of the printing, the vacuum of the belt and the movement of the belt can all be controlled by easy-to-use pedals.

Agfa-made inks: the perfect match

Agfa-made inks: the perfect match

Agfa-made inks: the perfect match

formulated to print on rigid or flexible media, Agfa’s GREENGUARD Gold-certified UV LED inks broaden the scope of possible applications. This is what you can expect:

- Wide color gamut

- Versatility & reliability

- Low ink consumption

- Excellent adhesion and durability

- Advanced white printing

- Compliance with industry norms

UV LED print technology

Equipped with UV LED lamps for the curing process, the Anapurna series offers major advantages in terms of performance, costs, maintenance, the environment and the generation of extra business.

Discover the benefits of UV LED

World-class training and support, anywhere you need it

If you purchase an Agfa solution, your operators will get trained directly by Agfa’s global support team. Have a question or did you run into an issue? Our experienced service technicians and application experts throughout the globe are available when you need them.

Technical data

Jeti Bronco H3300

| PRODUCTIVITY | |

| Express Mode Production Mode Standard Mode High Quality Mode | Up to 248 m²/h – 2669 ft²/h 75 – 100 m²/h (807 – 1076 ft²/h) 42 – 60 m²/h (452 – 646 ft²/h) Up to 25 m²/h (269 ft²/h) |

| MEDIA & PRINTING SPECIFICATIONS | |

| Rigid media | |

| Maximum width | 330 cm (130”) 320 cm (126”) with borderless printing |

| Maximum length | Supported by 1 rigid roller table: 192 cm (75.6 in) Supported by 1 rigid roller table + media extension table (default): 320 cm (126 in) |

| Minimum size | A2 landscape (60 x 42 cm – 23.6 x 16.5”) |

| Thickness | Minimum thickness: 0.2 mm (0.008”) Maximum thickness: 50 mm (1.97”) |

| Maximum weight | 10 kg/m² on printing table (22 lb) |

| Flexible media | |

| Maximum width | 330 cm (130”) 320 cm (126”) with borderless printing |

| Maximum length | n/a – restricted by weight and diameter |

| Thickness | Min. 0.2 mm (0.08”) |

| Maximum weight | 0.31 kg (0.682 lb) per cm (0.4” in roll width, meaning 160 kg (353 lb) evenly distributed over the full 3.3 m (130”) width |

| Maximum roll outside diameter | Support for 3” core media rolls – maximum media roll diameter 35 cm (13.8”) |

| PRINT HEADS & INKS | |

| Print heads | Ricoh heads |

| Inks | CMYKcm + white |

| IMAGE & TEXT QUALITY | |

| High-quality prints | Up to 635 x 2400 dpi |

| Text quality | Positive: 4 point / Negative: 6 point |

| ENGINE DIMENSIONS & HEIGHT | |

| Printer dimensions (H x W x L) | 201 x 717 x 214 cm (79 x 282 x 84”) |

| Weight | 5,100 kg (11,244 lb) |

| ELECTRICITY & COMPRESSED AIR | |

| Electricity | 380 V 3-phase star connection with Neutral wire(3 x 32 A) 50/60Hz230V 3-phase delta connection without Neutral wire(3 x 32 A) 50/60 Hz |

| Compressed air | Oil free (class 1 according to ISO 8573-1 2010), 160 l/min compressor with 50 l barrel @6bar |

| SYSTEM INTEGRATION RIP / WORKFLOW SOFTWARE | |

| Integrated production solution with Asanti workflow software. | |