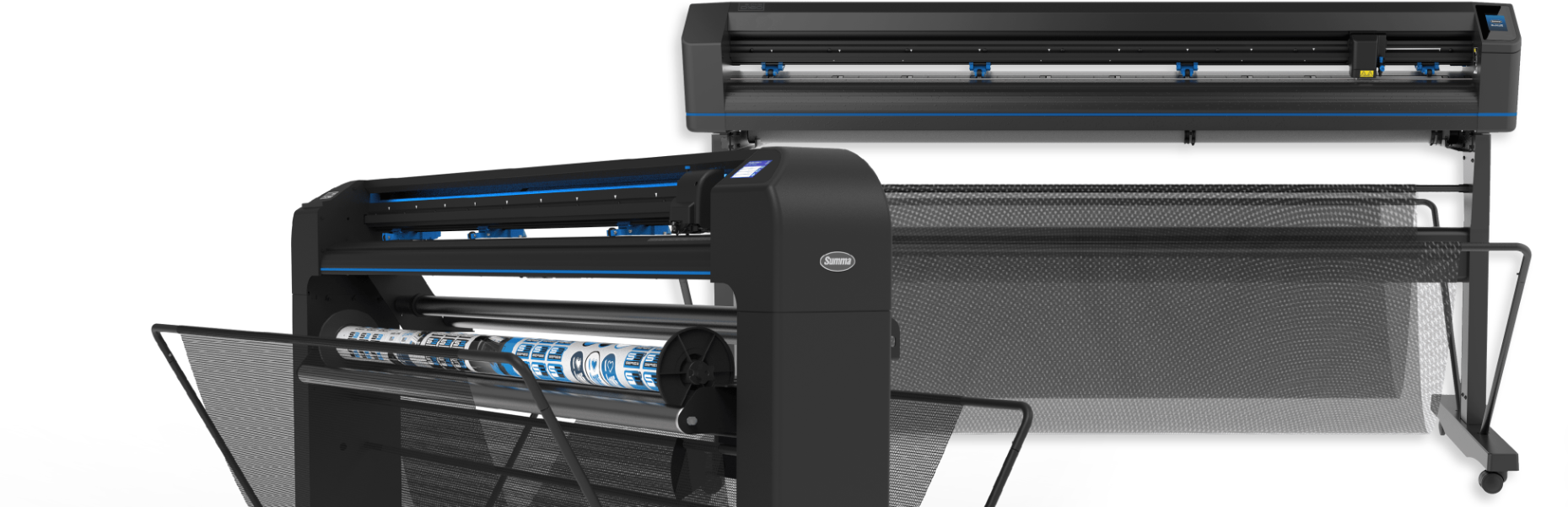

Roll cutter Series

Summa roll cutters, made to last

Summa roll cutters are designed on a foundation of rock-solid reliability and outstanding expertise. They feature the highest quality engineering and most advanced cutting technology to deliver high-end contour cutting accuracy for printed graphics.

Explore The Benefits of Our Vinyl Cutters

State-of-the-art Cutting Technologies

In the ever-evolving world of cutting, one technology doesn’t fit every bill. That’s why having a range of cutting technologies at your fingertips is paramount. Summa offers three top-of-the-line technologies: drag knife technology, tangential knife technology and dual head technology. Each has its own unique advantages. Read more about it here.

Advanced Cutting Features

Summa vinyl cutters are equipped with the most advanced cutting features on the market. These features optimize cutting quality and operational efficiency, addressing challenges from design to material transport. Providing you with an immaculate end result.

One of those advanced cutting features is the Summa Flexcut. Read more about it here.

Legendary Tracking Performance

Material transport is probably one of the most intricate aspects when cutting materials. The slightest error can result in material waste, loss of time, and operator frustrations. Summa offers a legendary tracking performance and extensive range of features to ensure your Summa S One or S Class 3 cutter performs perfectly and flawlessly. Find out more.

Internal Intelligence

Summa cutters are loaded with intelligent routines, optimising the cutting data. All Summa cutters use an advanced vector look-ahead technology that cuts complex images and lettering with improved efficiency. The cutting time is reduced considerably, curves are smoother, and the motors are less taxed, which increases the lifetime of the cutter.

Registration Marks (OPOS Contour Cutting)

Summa’s automated contour alignment system OPOS stands for Optical Positioning System. The OPOS sensor registers printed squares around the graphic. This allows OPOS to determine the exact position of the printed graphic and enables you to die-cut valuable printed and laminated vinyl graphics with complete confidence and ease.

Twin workflow with F series flatbed cutters

To maximise productivity and flexibility in your finishing workflow, you can use the Twin Workflow. It combines the strength of a roll cutter with an F Series flatbed cutter. The Twin Workflow has been developed for users who want to optimise their equipment use. By using it, productivity and performance will be brought to a higher level. Read more

Our Roll Cutter series

S One Series

With the S One Series, Summa offers a future-proof and reliable cutting product line, perfect for starting sign makers. It’s designed based on years of experience, up-to-date techniques, and by listening carefully to the customers’ cutting needs. Various types of roll stock, such as flex and flock, vinyl, and soft sheet materials, can be processed efficiently and rapidly. A multitude of intelligent features combined with sleek ergonomics makes the S One Series the ideal roll cutter to grow with your business.

S Class 3 Series

Designed for top performance, the S Class 3 tangential and drag-knife cutters feature first-class engineering and advanced cutting technology. They are crafted to cater to the needs of true professionals who demand nothing short of top-notch performance, pinpoint precision, and unparalleled versatility in their work. With their advanced technology, intuitive software GoSign, durable construction, and time-saving features, the S Class 3 roll cutters surpass even the most demanding user expectations.

Leave nothing to chance and enjoy our leading-edge contour cut excellence!

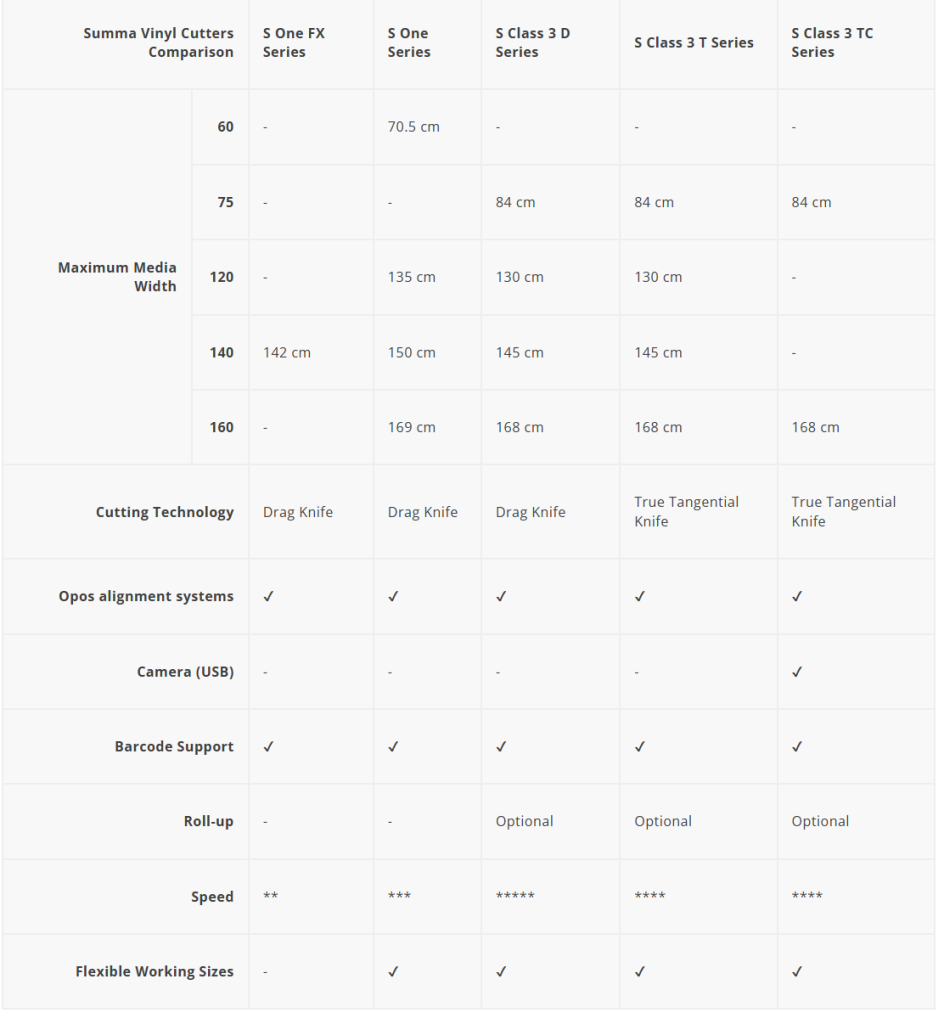

Summa Roll Cutter Comparison

Our teams are happy to advise you on a model that suits your business best.